Our Drum Handling Equipments

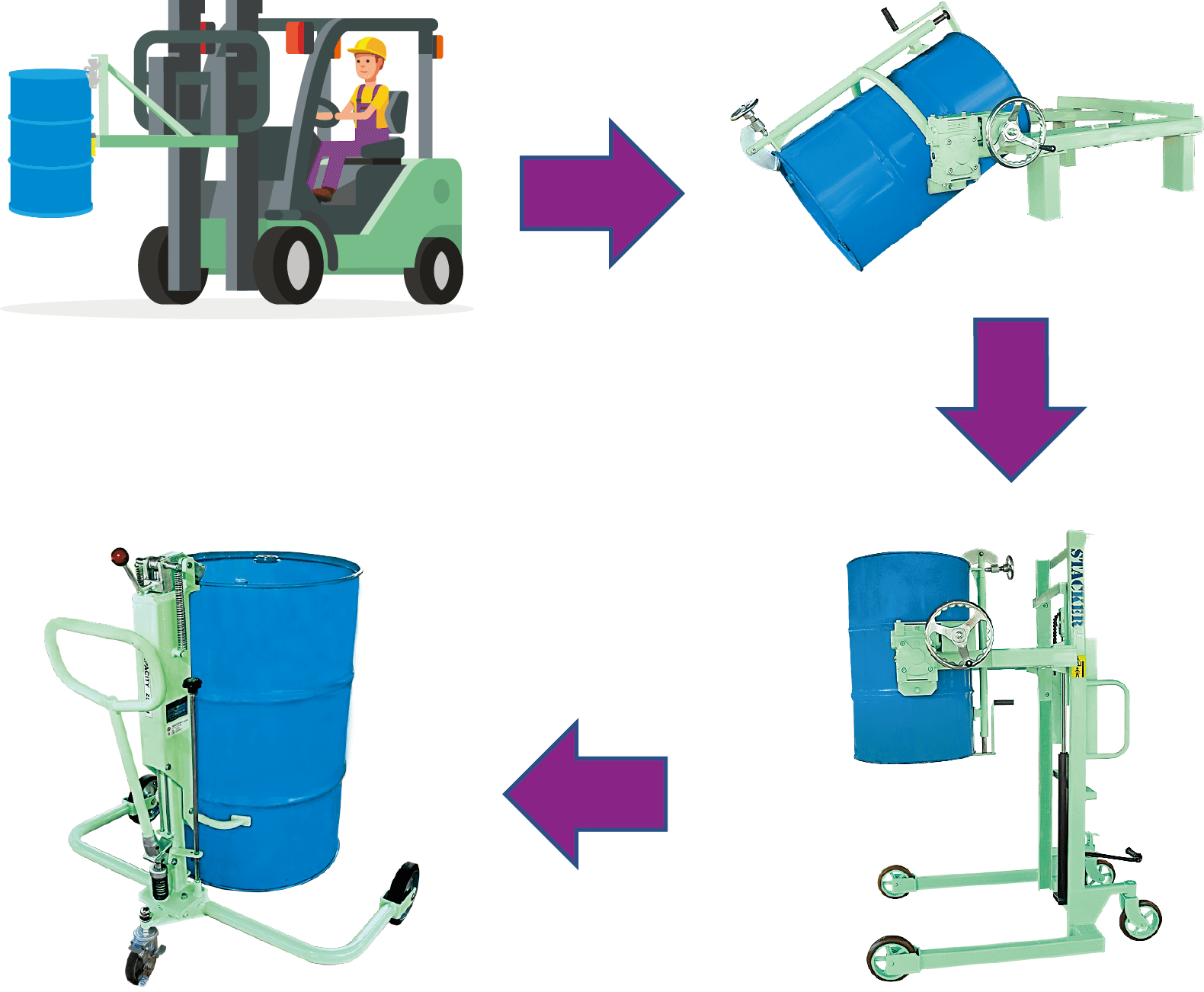

Our range includes Drum Gripper and Drum Tipper which are attachments to forklifts.

Or, with the absence of forklift, stand alone equipments like Drum Porter, Drum Lifter and Drum Handler are the solution to improve handling of drums in a productive and safe manner.

Find the best handling equipment for your drums in Malaysia now.

Our Solutions For Drum Handling Equipments

Drum handling equipments are particularly used in factories which involve drums in their daily operation – food & beverage, chemical, oil & gas and pharmaceutical industries.

Manually drum handling is at risk of accidents

Our Solutions

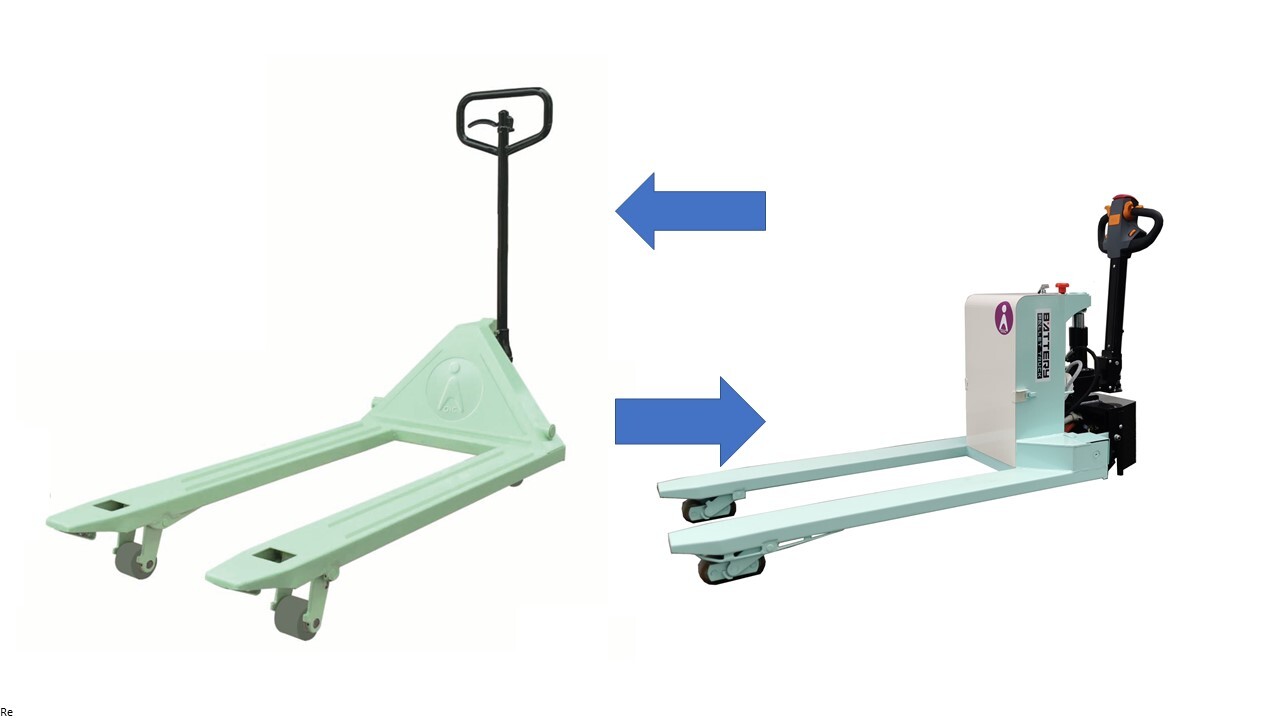

Manual Hand Pallet Trucks / Battery Pallet Trucks

Our standard range of 2.0 T & 2.5 T hand pallet trucks and 2.0 T battery pallet trucks are the solutions to improve transferring of pallets in a productive and safe manner.

Find the best pallet trucks for your pallet movement in Malaysia now.

Our Solutions for Pallet Trucks

Our Solutions

Our Lift Tables

Our standard range includes different models of manual lift table in order to suit different requirements of the consumer.

Battery or electric operated lift tables as well as special design can be custom- made according to individual's needs in order to promote safe working environment and increase in productivity.

Our Solutions for Lift Tables

kind of industries for the purpose of lifting heavy objects.

Manual lifting is at risk of accidents and ergonomic issues

Our Solutions

DRUM HANDLING EQUIPMENT

Drum Gripper, Drum Tipper, Drum Porter, Drum Handler

2) To grip and stack drums on rack

3) To load/unload drums from lorry

4) To discharge content out from drums

5) To handle drums with any form of luquid espcially dangerous chemicals

6) To transport drums from ground or pallets, and move within narrow space

PALLET TRUCK

Manual Hand Pallet Trucks, Battery Pallet Trucks

2) Compact; ideal to move within narrow space especially inside the container

3) Convenient & comfortable to operate

MANUAL LIFT TABLE

Lift Table, Hydraulic Lift Table, Scissor Lift Table

2) To load & transfer heavy object on to/off the rack

3) To load / unload mould from machine

4) Compact, ideal to move within narrow space

Case Studies in Malaysia

Lift Table - LTX-H250-8EC

After using our lift table, the workers no longer need to bend their body up and down. By just pumping the foot pedal, the entire lift table will rise to the desired height. The Factory Manager does not have to worry anymore about the back injuries and production runs smoothly without any hic-ups.

Drum Gripper - Auto N-2

Drum Porter – DL-350

Multi Drum Porter – DL-350MD

Drum Handler – PL-H300-12DT M

OIC-25L-122D

BPT-2000 ERA L

Our Service

Contact us

DROP US A MESSAGE